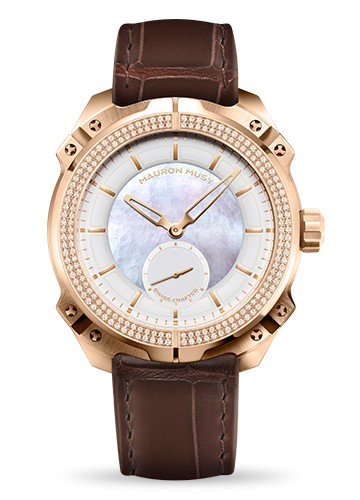

Innovative watch engineering

It took us three years of research and development, backed by unfailing optimism and tenacity, to develop the nO-Ring® technology. A truly disruptive innovation, this patented system relegates O-ring seals to the rank of historical curiosity. Based on the principle of mechanical sealing technology, this 100% Swiss Crafted device guarantees absolute security while avoiding the need for costly recurrent maintenance service. The watch industry had seen no significant breakthroughs in this field for over 130 years.

Eric Mauron

Christophe Musy